- Company

- Business areas

- Solutions

- Services

- Products

- Representative

- Projects

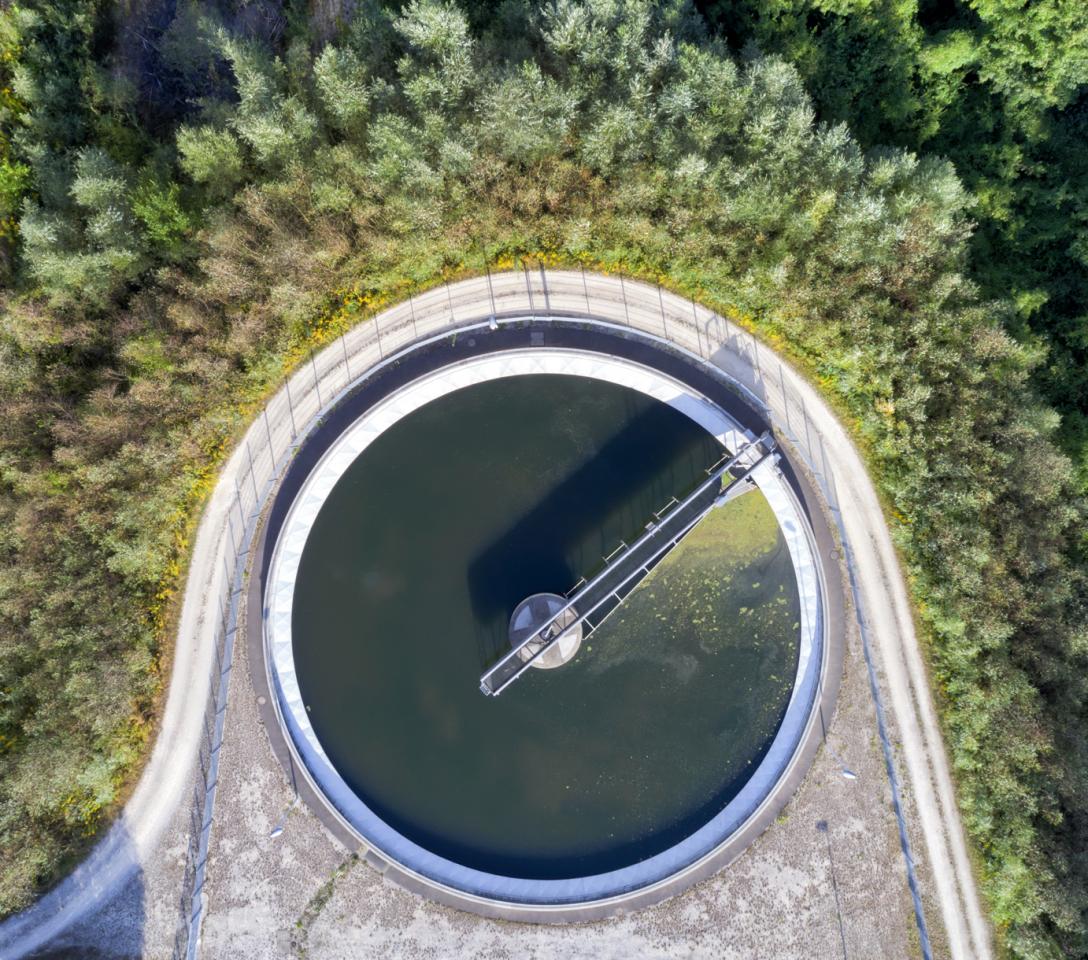

Effective sludge reduction. Less sludge. More gas. First-rate balance.

Optimum sewage sludge treatment, stable digestion operation and reduction of costs – this is what reverse flow disintegration (GSD) with ultrasound, a patented process from VTA Technologie GmbH, has to offer.

In VTA GSD, ultrasonic transducers digest the thickened sludge flowing through the disintegration reactor.